In this article, we’re going to take a look at 12 types of process improvement methodologies.

A great business process drives efficiency, scalability, repeatability – and minimises inconsistency, both in the ‘output’ of your product or service, and the experience of your customer.

But while ‘process’ brings structure to businesses, that doesn’t mean things can never change.

Quite the opposite.

Processes need to evolve, and grow – so innovation is key.

That’s where process improvement methodologies come in. These methodologies are not about seeking out new ways to work – but rather really going deep on improving your existing business processes and making them work as hard as possible for you and your team.

What is process improvement?

Process improvement is a methodology within project management. It’s where you look at the processes you have in place, and try to make them work more efficiently. There may be specific objectives but generally the aims will be to reduce errors, cut waste, improve productivity and – ultimately – make a business work better, for its customers and its staff.

Process improvement has other names, too (more wordy ones!) You might hear people talking about business process management (BPM), business process improvement (BPI), business process re-engineering, continuous improvement process (CIP) and plenty of others.

But for now, let’s stick with ‘process improvement’ and take a look at some of the models people use to get it done!

What are the main process improvement methodologies?

1. Kaizen

2. 5s

3. PDCA

4. Six Sigma

5. Cause and Effect Analysis

6. SIPOC Analysis

7. Value Stream Mapping

8. Total Quality Management

9. Kanban

10. Process Mapping

11. The Five Whys

12. Lean Manufacturing

The goal of simply ‘making your business better’ is pretty overwhelming – it’s hard to know where to start.

That’s why there are a number of structural, continuous improvement methodologies for actually doing this important work. Using one, or a number of these, will put you in a great position to improve the processes that drive your business!

1. Kaizen

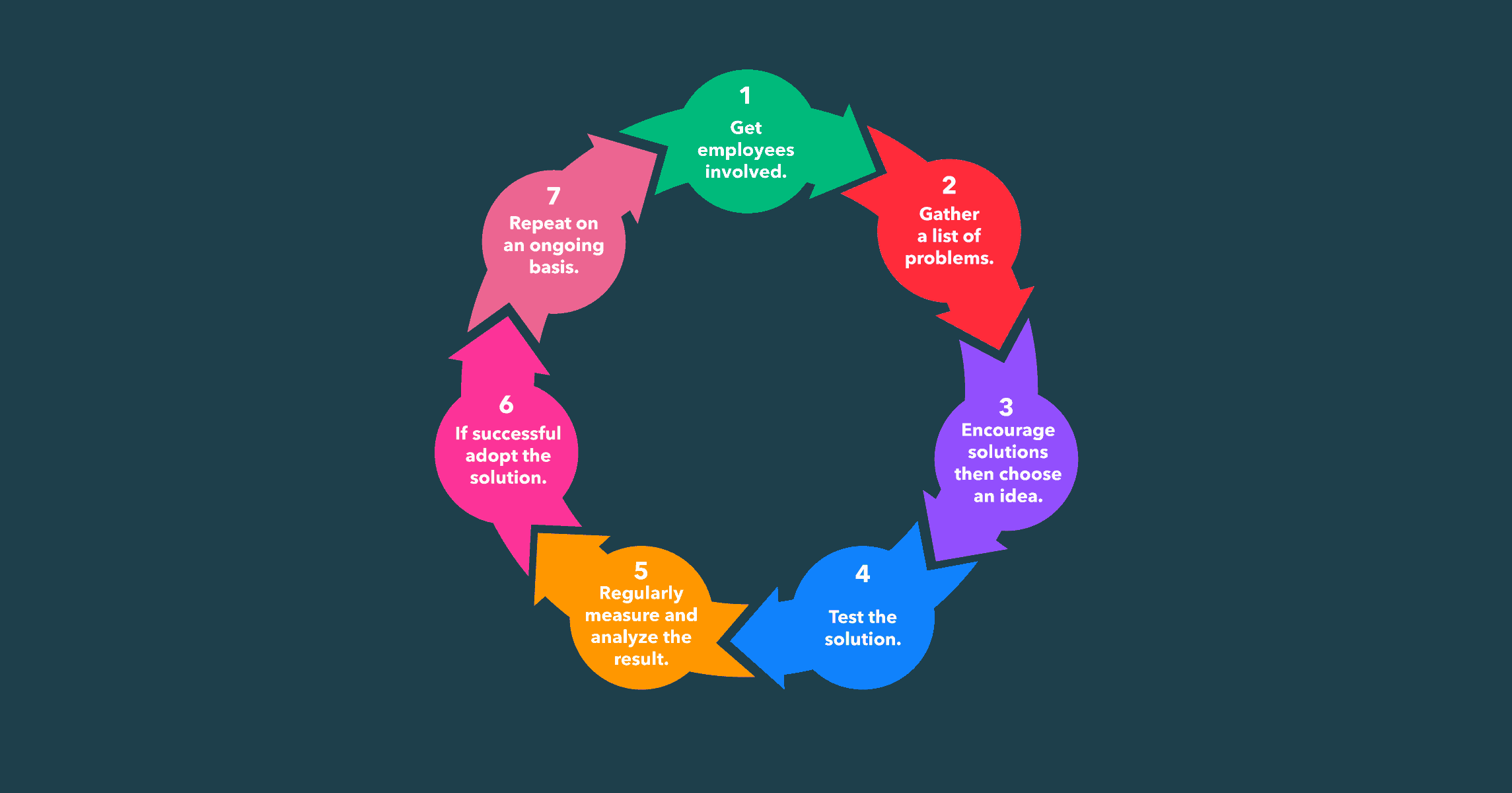

Kaizen is a Japanese word that means “improvement” or “change for the better.” The Kaizen philosophy is based on the idea that small, continuous improvements can lead to big results over time.

In the process improvement context – like other process improvement methodologies – it’s about ongoing tests and changes to incrementally make things a little bit better.

It also depends heavily on the involvement of the people delivering your process – namely your employees.

2. 5s

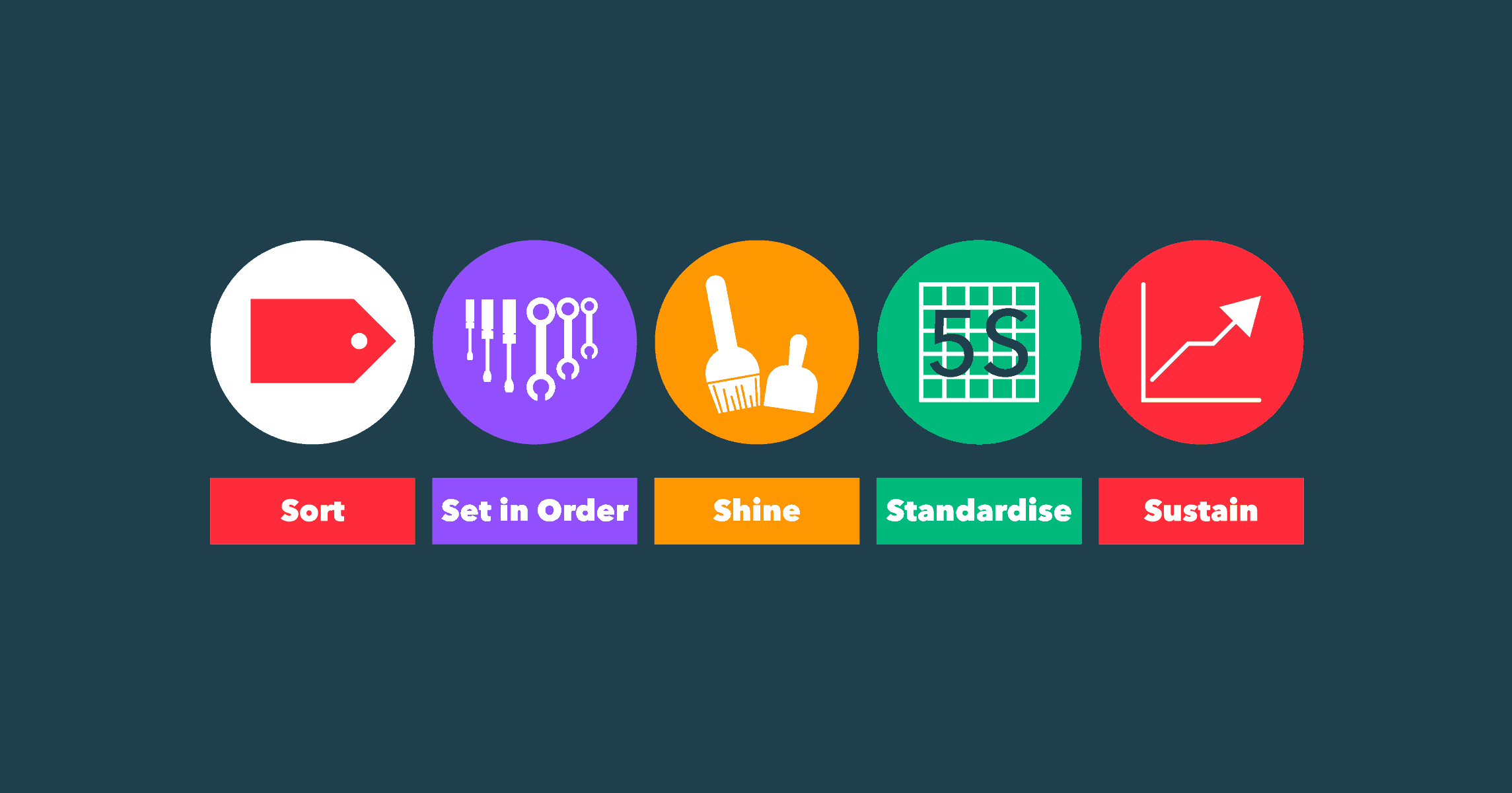

5s was also first developed in Japan as a way to improve manufacturing processes, but it has since been adopted by businesses all over the world as a way to improve any type of business process.

The 5s methodology is based on the following 5 principles:

2. Set in Order: Arrange all necessary items in the workplace so that they are easy to find and use. This helps to improve efficiency and productivity.

3. Shine: Clean and maintain the workplace on a regular basis. A clean and well-maintained workplace is essential for maintaining high standards of quality.

4. Standardise: Establish standard procedures for all activities in the workplace. This will help to ensure consistent quality and performance.

5. Sustain: Maintain the 5s system on a continuous basis. This will help to ensure that the benefits of 5s are realised over the long term.

The 5s methodology can be used to improve any type of business process, but it’s particularly effective in manufacturing and production environments.

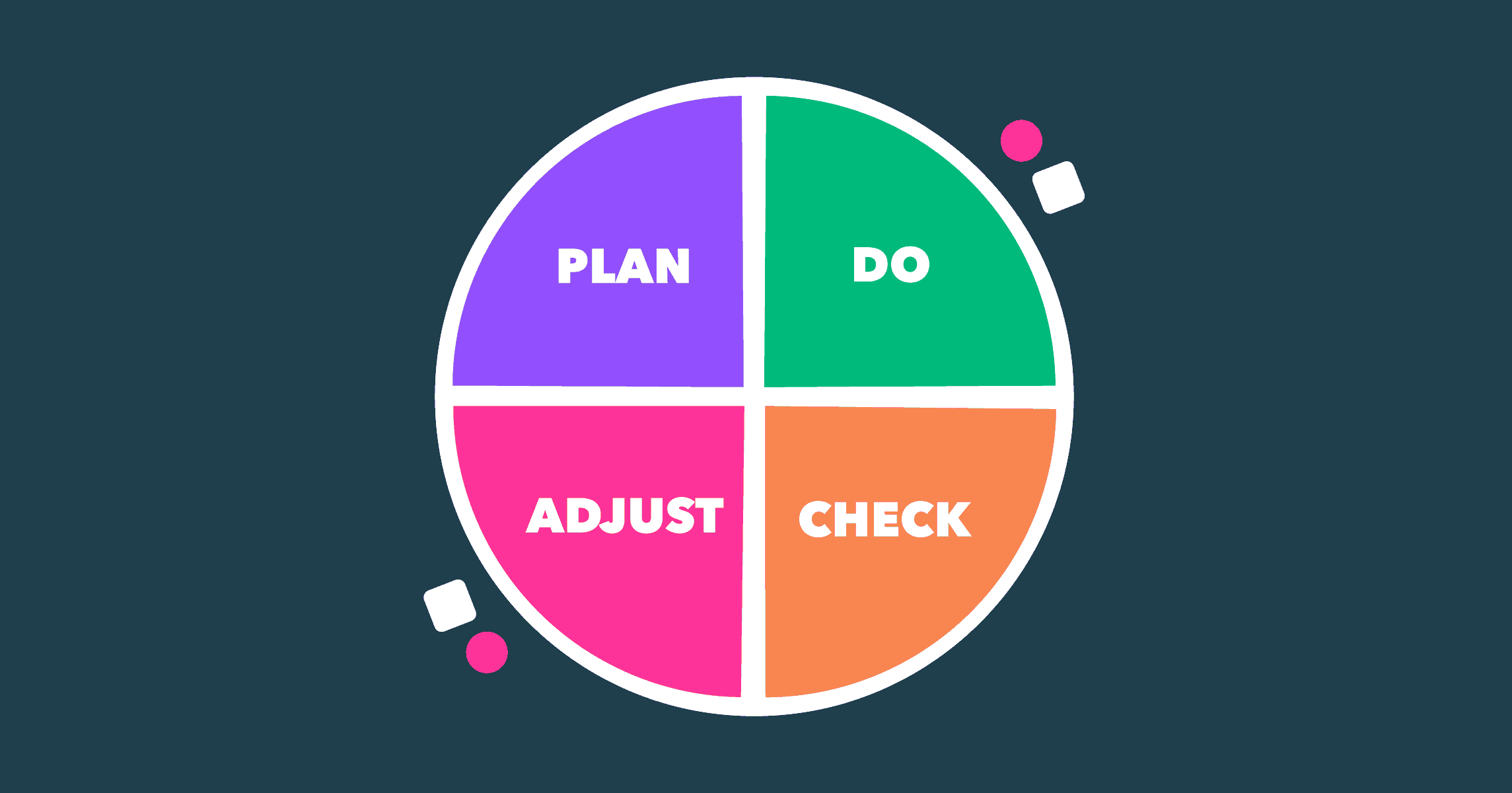

3. PDCA – Plan, do, check, adjust

PDCA is a four-step process improvement, which stands for plan-do-check-adjust.

The PDCA cycle can be used to improve any process, from manufacturing to customer service.

Here’s a quick overview of each step in the PDCA cycle:

2. Do: The second step is to put your plan into motion. This is where you’ll actually make changes to the process.

3. Check: Once you’ve made changes to the process, it’s important to track and measure the results. This will help you determine whether or not the changes are having the desired effect.

4. Adjust: The final step is to adjust the process based on what you’ve learned from tracking and measuring the results. This might involve making further changes to the process, or it might mean reverting back to the original process if the changes didn’t have the desired effect.

The PDCA cycle is an iterative process, which means that it can be repeated as many times as necessary.

One of the benefits of PDCA is that it forces you to think systematically about process improvement. It’s not enough to just make random changes and hope for the best. PDCA forces you to plan out your changes, track the results, and adjust accordingly.

Another benefit of PDCA is that it can be used by anyone, at any level within an organisation. It’s a simple process that doesn’t require any special training or skills.

4. Six Sigma

There are two ‘six sigma’ approaches to process improvement – DMAIC and DMADV. However, DMADV is more about implementing new processes. Since we’re focusing specifically on process improvement methodologies here, we’re going to stick with DMAIC.

DMAIC is a process improvement methodology that stands for Define, Measure, Analyse, Improve, and Control.

2. Measure the current process performance.

3. Analyse the process to identify problems or opportunities for improvement.

4. Implement the solutions you’ve come up with and designed. These improvements should aim to address root causes of process problems or to capitalise on process opportunities.

5. Control the process with ongoing monitoring and measurements, to ensure the improvements actually last!

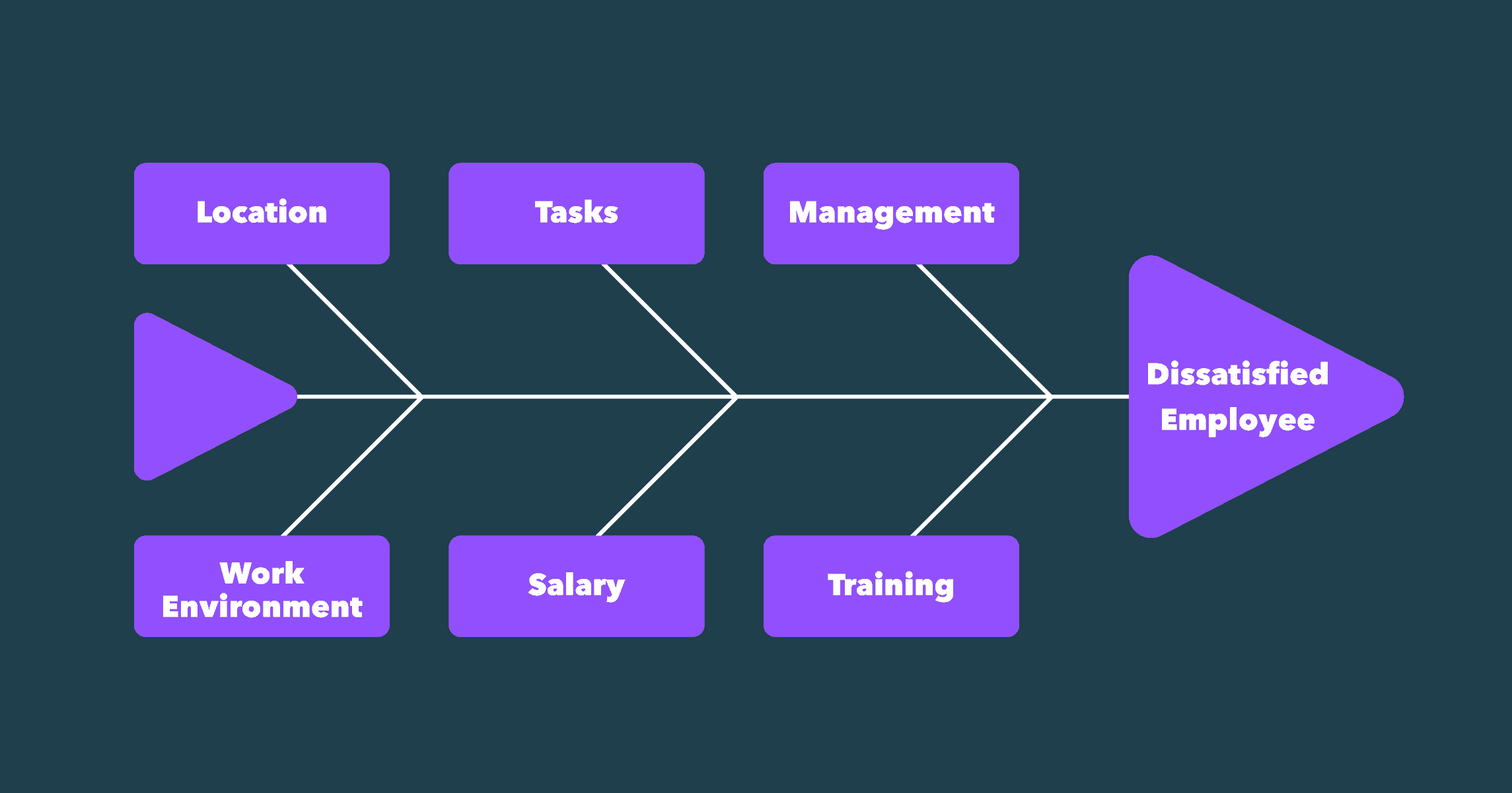

5. Cause and Effect Analysis

Cause and Effect Analysis is another one of our continuous improvement methodologies that finds its origins in Japan. It’s also known as the Fishbone Diagram – you can probably see why!

A problem is identified on the right and becomes the head of the fishbone. This is also known as the ‘Effect’. Then we have the ‘Causes’ outlined behind this, and they are visualised as extending from the spine of the fish.

By taking the time to understand the causes and effects of problems, you can make targeted changes that lead to real results. And that’s something everyone can benefit from!

6. SIPOC Analysis

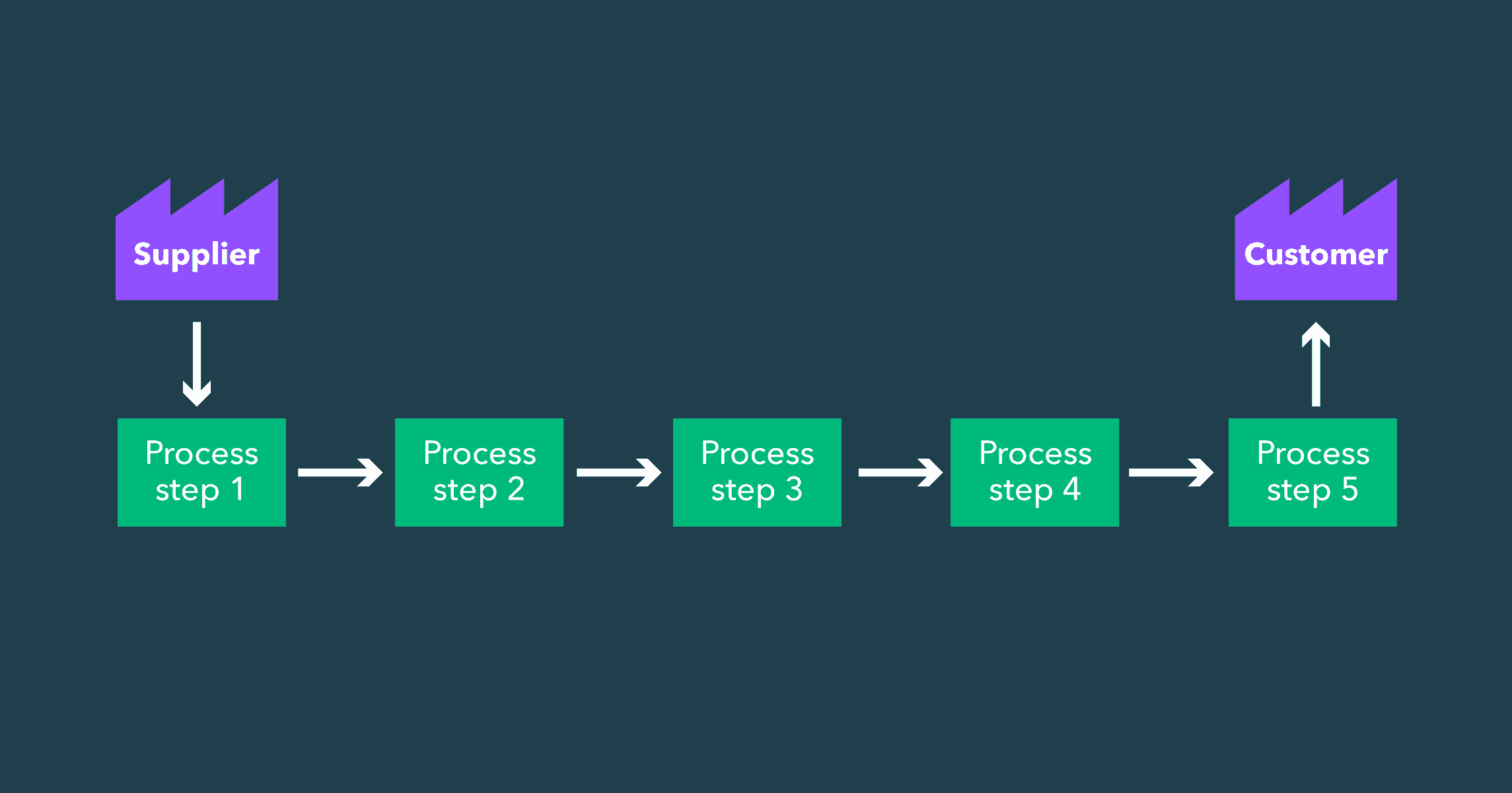

A SIPOC analysis is a process improvement tool that can be used to understand and map out the key components of a process. It stands for Suppliers, Inputs, Process, Outputs, and Customers.

It’s about really taking things back to basics and laying out your whole business on paper. The steps you’re looking at are:

2. Inputs. Next, you’ll need to identify the inputs themselves. These are the things that go into the process, such as raw materials, information, or labour.

3. Process. Once you know the suppliers and inputs, you can start mapping out the process itself. This step involves identifying all of the steps involved in taking the inputs and turning them into outputs.

4. Outputs. After the process has been mapped out, you’ll need to identify the outputs of the process. These are the things that come out of the process, such as finished products, services, or information.

5. Customers. Finally, you’ll need to identify the customers of the process. These are the people or organisations who receive the outputs of the process.

Conducting a SIPOC analysis can help you to understand a process and identify potential areas for improvement.

It can also be used to communicate complex processes to others in a clear and concise way.

7. Value Stream Mapping

Value Stream Mapping is a process improvement methodology that can help you understand and optimise the flow of your process.

It’s about mapping out the steps in your process – and by doing this, you can identify the ‘value’ of each step, as well as working out any bottlenecks and inefficiencies that are getting in the way of you achieving the best results!

Additionally, Value Stream Mapping can help you visualise your process so that you can more easily see where improvements can be made.

8. Total Quality Management

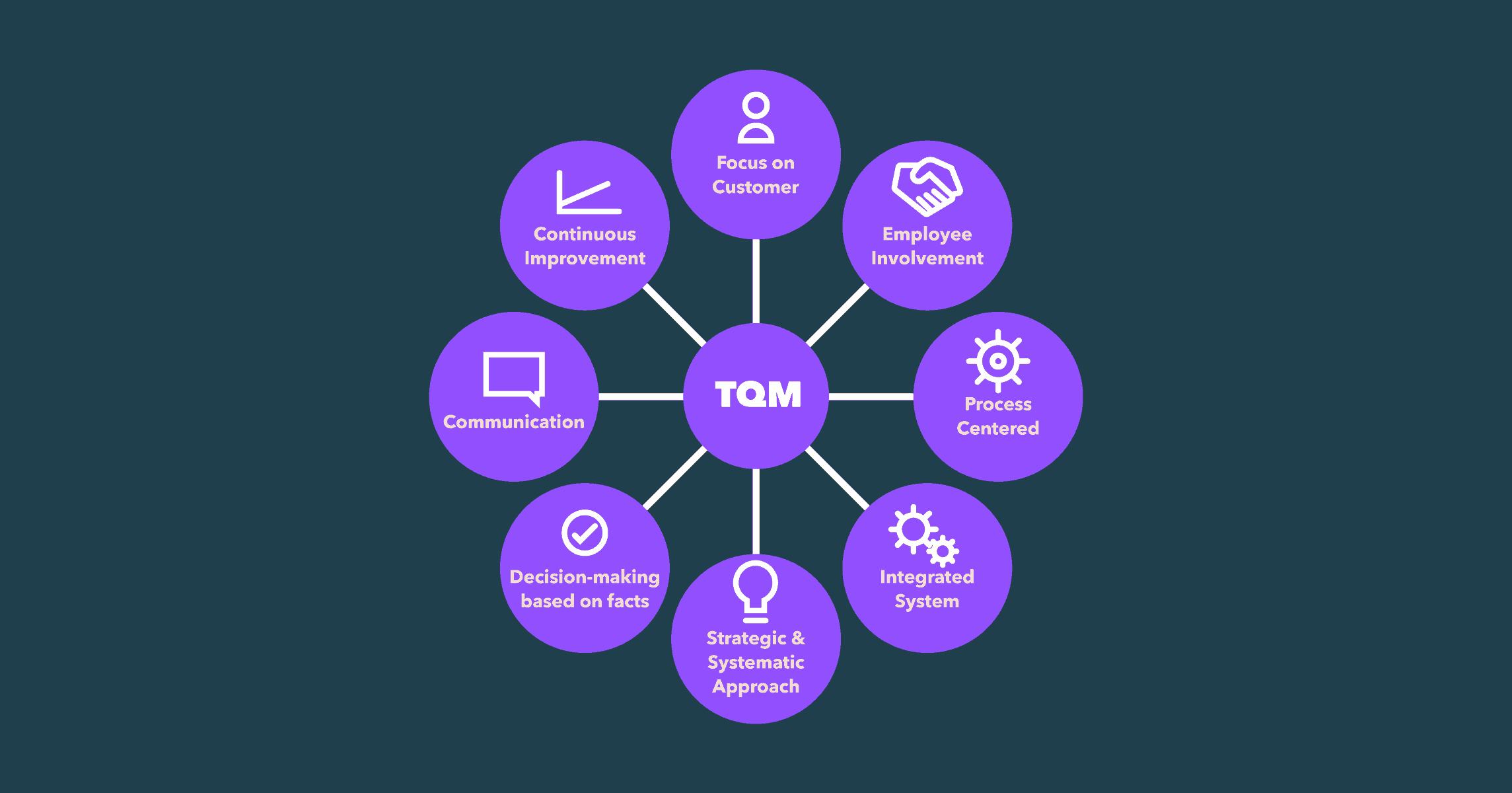

Total quality management (TQM) is a process improvement methodology that emphasises the need for all members of an organisation to be involved in the process of continual improvement.

The key components of TQM are:

– Continuous process improvement

– Involvement of all members of the organisation

– Use of data and statistical methods to drive decision making

– A culture of open communication and collaboration

TQM has its origins in the work of W. Edwards Deming, who was instrumental in helping Japanese businesses rebuild after World War II (Japan are really into their process improvement methodologies aren’t they?!). Deming’s ideas were later adopted by other industries all over the world, including healthcare, manufacturing, and service organisations.

TQM is an important tool for process improvement because it helps to ensure that all members of the organisation are working towards the same goal of providing quality products and services to customers.

A culture of open communication and collaboration is essential for TQM to be successful. All members of the organisation need to be involved in the process of continuous improvement, and they need to be able to share ideas and feedback freely.

Organisations that adopt TQM principles will find that they are better able to compete in the marketplace and deliver superior value to their customers.

9. Kanban

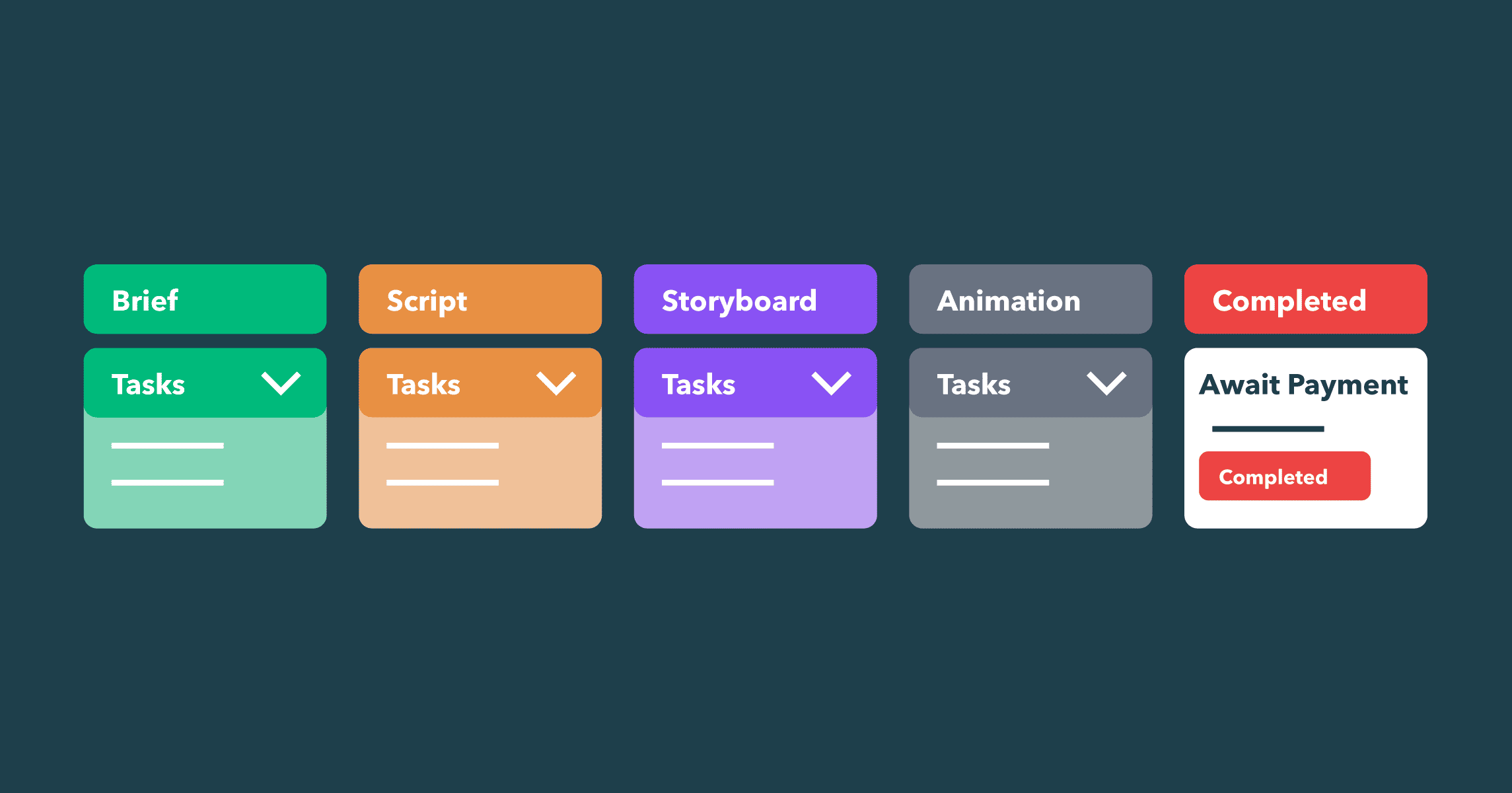

Kanban is one of the most effective process improvement techniques that helps businesses streamline their operations and get more work done efficiently.

The kanban system is based on the principle of visualising work, which helps to identify bottlenecks and optimise workflow, and it originated in – you guessed it – Japan! The Toyota factory, to be precise.

If you’re thinking of implementing kanban in your business, there are a few things you should keep in mind. First, you’ll need to define what work needs to be done and break it down into smaller tasks.

Next, you’ll need to create a visualisation of your process, which can be done with a Kanban board. Finally, you’ll need to establish some rules and guidelines for using the Kanban system.

The benefits of kanban are plentiful, but some of the most notable include improved process efficiency, better communication and collaboration among team members, and reduced cycle times.

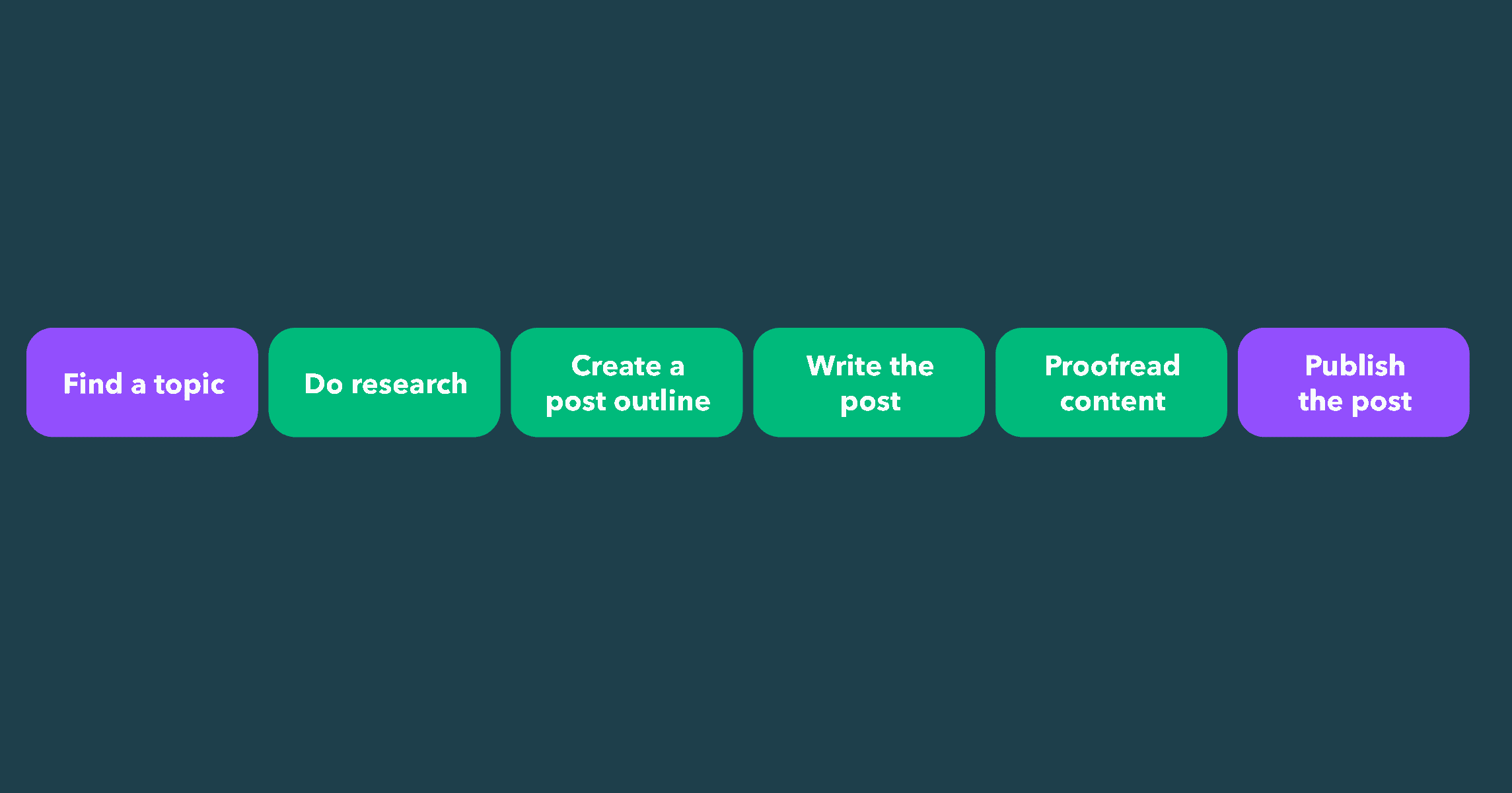

10. Process Mapping

Process Mapping involves creating a visual representation of a process, and then looking for ways to optimise that process.

By understanding the steps involved in a process, and how they relate to each other, businesses can find ways to make their processes more efficient and effective.

Once a process map has been created, it can be used to identify bottlenecks, inefficiencies, and areas where improvements can be made.

You can then look for the difficult/unnecessary/duplicated work and try to create a more streamlined business process.

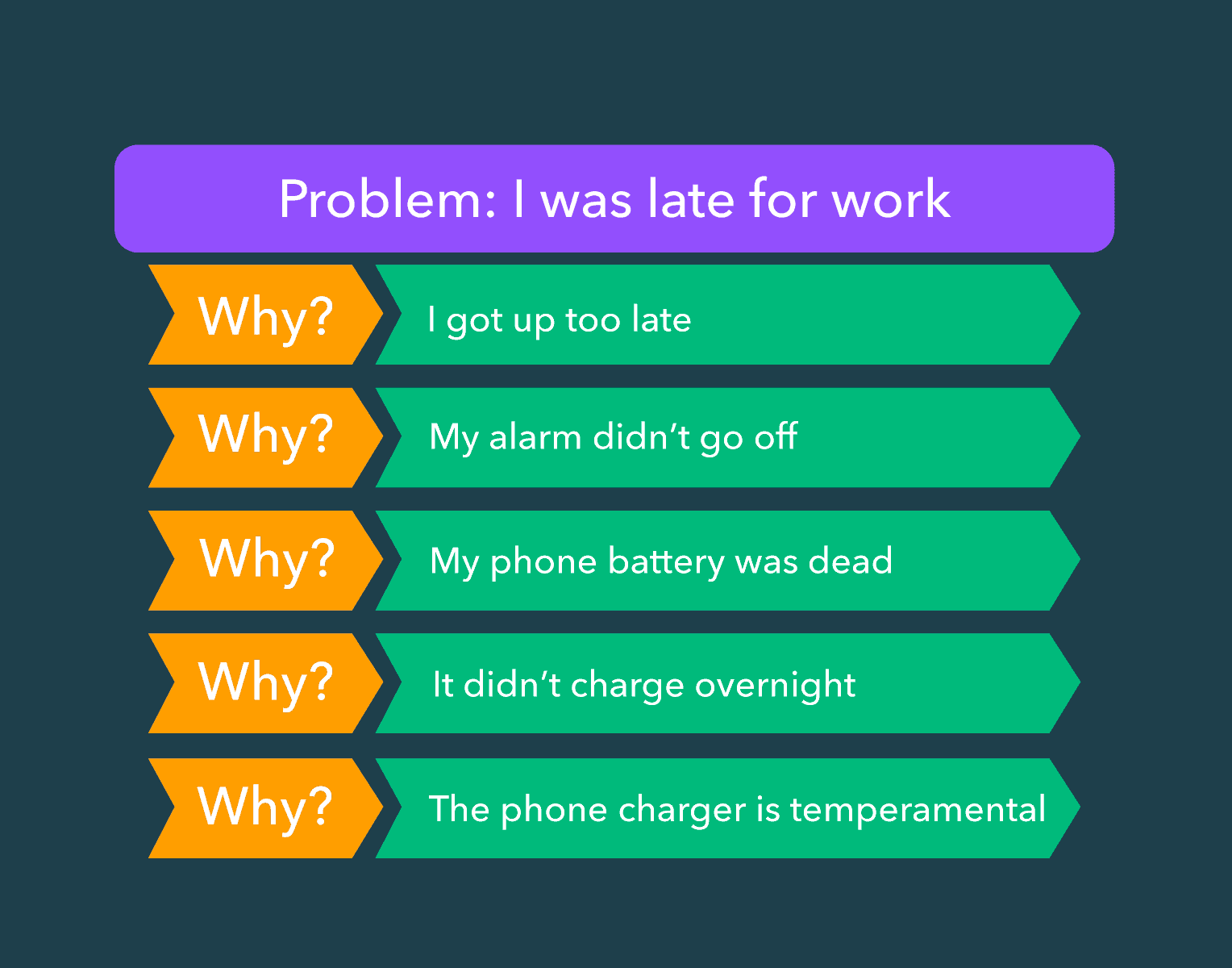

11. The Five Whys

The 5 Whys (also sometimes known as the Root Cause Analysis) is an iterative interrogation technique used to identify the root cause of a particular problem.

In simple terms, it goes like this:

- Identify issues

- Manipulate the solution by – like an annoying kid – repeatedly asking ‘why?’

The idea is that, eventually, you will reach the root cause of the problem, and put yourself in the best possible position to fix it.

This is a useful model because it stops you wasting time treating ‘symptoms’ and gets you right to the very heart of the fundamental problems that are holding back your business.

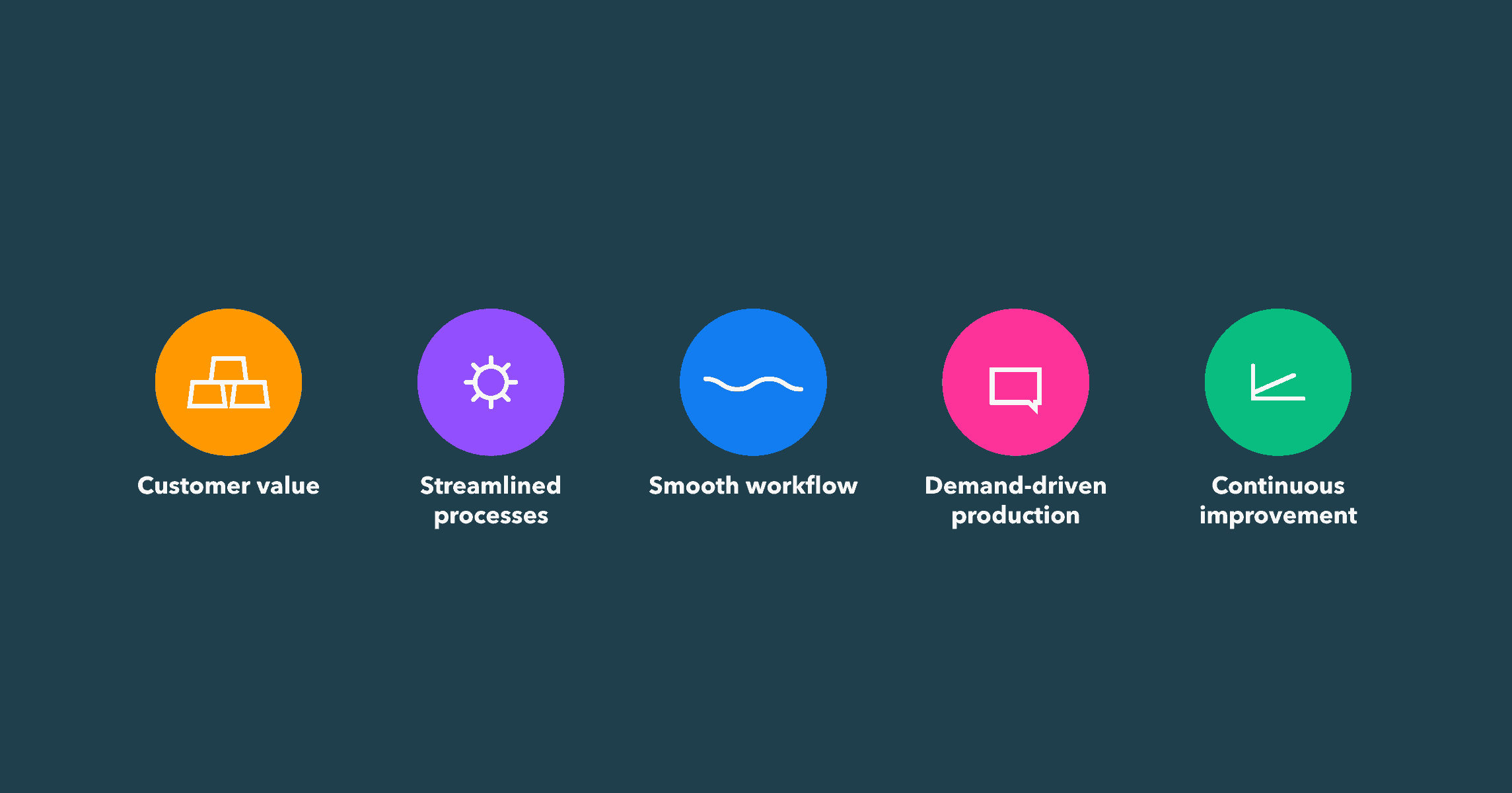

12. Lean Manufacturing

Lean Manufacturing is process improvement methodology that aims to eliminate waste and maximize value for customers. Lean Manufacturing focuses on creating more value with fewer resources, resulting in lower costs, higher quality, and increased customer satisfaction.

The 5 principles of Lean are as follows:

2. Streamlined processes

3. Smooth workflow

4. Demand-driven production

5. Continuous improvement

By following these principles, you can work to identify and eliminate waste, reduce lead times, increase productivity, and improve profitability.

The benefits of process improvement

– Culture. A culture of continuous improvement – which challenges everyone to be at their best – can be an incredibly motivating thing, leading to higher employee engagement and retention. In some environments it also helps drive a focus on safety.

– Innovation. Encouraging new ideas and ways of working can be a great way to keep your people on their toes. It can drive innovation at every stage of your process.

– Customer experience. Ultimately the main beneficiary of process improvement is your customer – they benefit from an improved process, a safer process, and better quality produce delivered by a motivated, engaged workforce.

Final thoughts

Looking to improve your business – make it more efficient, more productive, delivering a better service to your customers, and a better place for your employees to work – is what process improvement methodologies are all about

The models outlined in this post overlap in many ways. They each have their strengths and weaknesses, and their own suitability for different types of businesses and processes.

Whichever you go with, being immersed in process improvements gives you the best possible chance to improve your outputs, increase efficiency, reduce waste and delight your customers – while improving all your existing processes.

(And, since you’re here, if those are your goals – make sure to take our project management tool for a spin!)